The Iron Casting Process Explained

The process of casting has been around for a long time. According to Haworth Castings, the casting process has been in practice for more than 5,000 years. The oldest example of casting is a copper frog that has been around since 3,200 B.C. Throughout the rest of this article, let's talk more about the steps involved in the manufacturing process known as iron casting.

Iron Casting Design

The first step of the iron casting process involves engineering the design of the desired product. During this phase, the designers will approximate the final product to determine how to create it. They may use computer programs to create a more accurate 3D model of the item they want to produce. After they've settled on the final product's appearance, they will select the molding method most capable of creating it with minimal trouble.

Patternmaking

With the designs for the product established, the workers can now focus on patternmaking. Patternmaking is part of the process during which the workers create the molds for casting. The patterns are often made out of metal, plastic, or wood.

The patterns used to create the molds must be highly accurate. They must also offer allowance in different ways to ensure that the items made through casting are correctly proportioned. You should also be able to remove the pattern from the mold without disturbing the latter.

Core Making

The iron casting process may also involve core making. Core making is necessary if the final product is supposed to be hollow. The product makers will use a core made from either sand or metal to form that sought-after hollow shape.

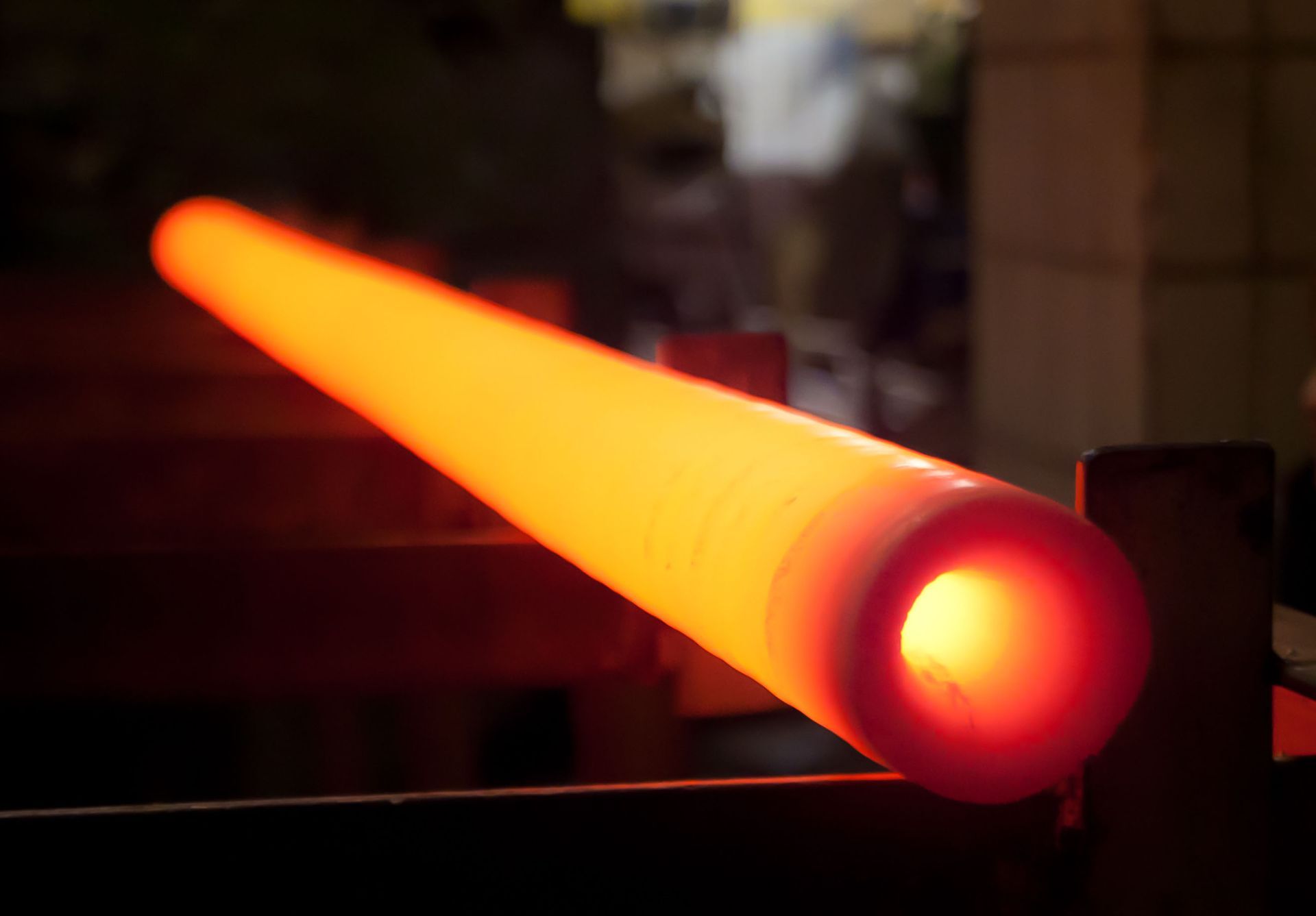

Melting and Pouring Iron

With the mold finally ready, the workers can start melting the iron. After the iron is melted, it is carefully poured into the prepared mold. The liquid metal is then allowed to sit in the mold until it cools and solidifies.

Mold Shaking

At this point, the product inside the mold may be covered in sand and other types of debris. The product must be cleaned before it is deemed ready. Cleaning the final product involves shaking the mold. All that shaking should remove any excess sand.

Machining

The workers finish the iron casting process through machining. Machining involves cleaning the product and making minor alterations to get the desired result. Once the product goes through machining, it will be ready for its intended application.

The iron casting process can be very complicated. Thankfully, our manufacturing experts are capable of executing it without any problems. Our team has over two decades of experience helping those like you get the iron castings they need. Reach out to us today at NRB Metals to hire our reliable team for your needs.

Share On: